Bolt-on sticks

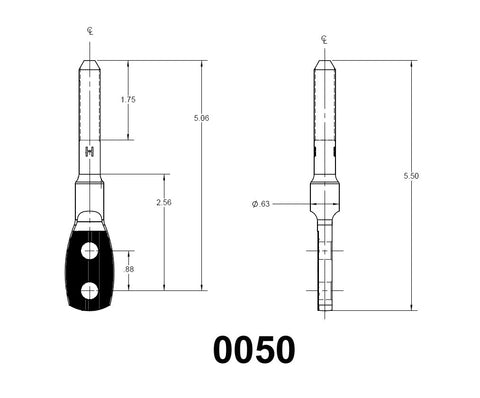

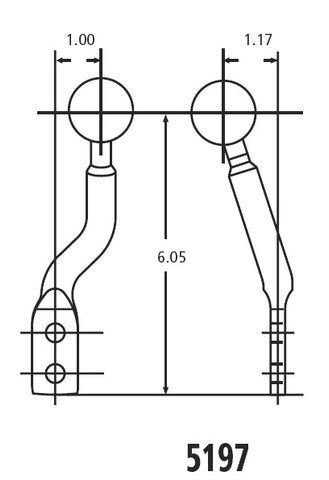

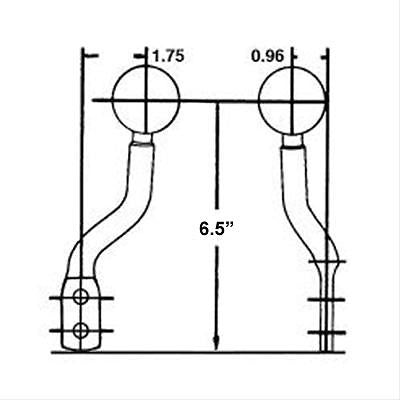

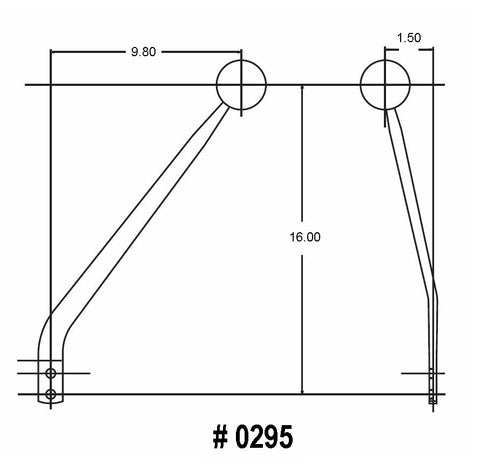

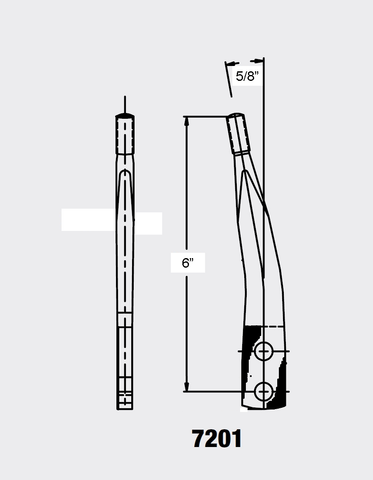

- Mount via two 3/8" holes spaced apart 7/8" on center

- Mating serrations on one face (left in most cases) to engage a stub with matching features; alternatively the smooth side can be mated to a smooth surface

- Chrome sticks have 3/8"-16 knob thread; a knob or T-handle is required (sold separately)

For custom jobs - stated applications are irrelevant once the trans is changed. Don't define stick length arbitrarily; focus on choosing a stick and base that together achieve your desired knob location. Proper leverage requires matching stick length with base fulcrum height but stick mount height varies with fulcrum height (see swap base page). Therefore consider the overall height and shape of the assembly to meet your objectives - NOT the individual parts alone

If you don't see what you need: Do not weld, bend, or modify a case-hardened part like this as it will create a weak spot that can lead to catastrophic failure. Instead use an extension bracket to offset and rotate a slightly smaller stick to your dimensions - example. We have a few brackets to offer; otherwise use 5/16" thick mild steel, maintain a minimum neck width of 1", and do not exceed ~3" of offset in any direction. (Find a buddy w/ a CNC laser cutter..) Mate this bracket to smooth faces on stick and stub with silicone RTV and 3/8" mounting bolts into threaded holes. Make sure bracket shape does not cause interference across range of motion, and that it allows the use of a dust boot to cover the shifter mechanism

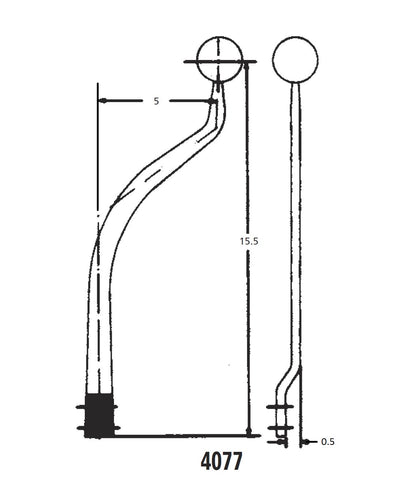

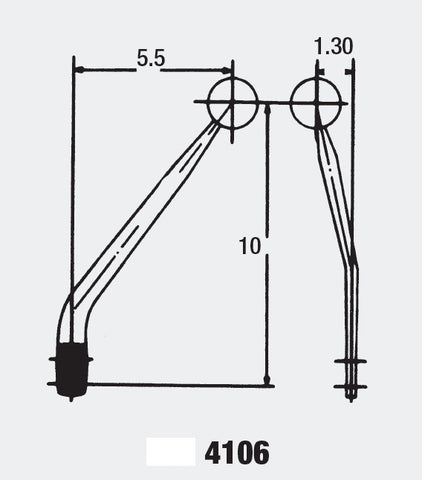

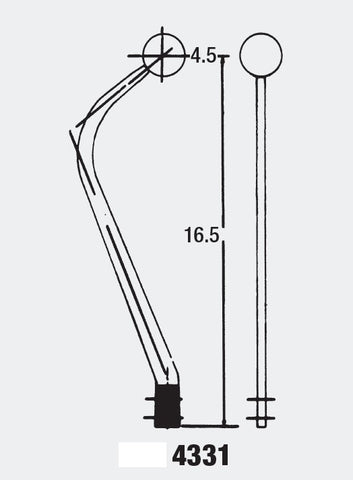

See the stick charts page for spreadsheets to quickly figure out which stick(s) have the height and rear offset you need

Check out the accessories page for floor boots & stick hardware (bolts, brackets, etc)